Keit: Furniture for Airports

How can airport furniture make flying more comfortable and enjoyable for all passengers? To answer that question, I designed a modular furniture system based on extensive research, workshops and user interviews for my Capstone project at University of Cincinnati’s college of Design, Architecture, Art, and Planning.

Role: 3D design, design research, graphic design

How can airport furniture make flying more comfortable and enjoyable for all passengers?

I've been fascinated by air travel and airplanes since a young age, but I've always been frustrated by the reputation that precedes air travel. When you talk about airport experiences, passengers often tell you about long delays, anxiety, and incredible boredom. With Keit, I wanted to explore how design can help make travel more comfortable by rethinking passenger waiting area furniture.

I recalled Brian Eno's ambient album, Music for Airports, a product specifically designed for the space. Eno began composing the album after a flight from Frankfurt's airport, where he recalls a beautiful sunrise over the airfield, accompanied by canned pop music. He felt the terminal required its own soundtrack, and set out to create the world's first ambient album, with the intention that the music should be "as ignorable as it is interesting" (see the whole interview here). I took this viewpoint as inspiration, and set off to create furniture that meets passengers' needs, while integrating itself seamlessly into their journey.

The Customer is Always Right

Airports are distancing themselves from airline revenue in search of more stable and lucrative passenger revenue. What they’ve found is that happier travelers=happier shoppers.

An Opportunity for Change

Waiting room furniture has changed very little in the past century. Now, passengers find themselves waiting longer hours for more reasons than ever before. New airport furniutre must be as versatile as the passengers – accommodating their needs without getting in the way.

The Time is Now

As a result of airports diversifying, they are becoming more experience-focused. Take, for example, the wave pool at Munich International Airport. Designed to draw both travelers and city-dwellers alike, the airport is looking to become less of a processor of people and more of a civic institution, where passengers are encouraged to spend time, relax, and spend money!

Responding to Passenger Needs

Interviewing travelers and speaking with the customer experience team at CVG gave me insights into groups of travelers and how they each use the airport differently. Four primary user groups emerged from the research – business travelers, solo travelers, families with kids, and people traveling in groups. Each group used the space differently, but ultimately their needs could be summarized as...

Kid-Friendly

Families

Workspace

Business Travelers, Solo Travelers

Solo Seating

Business Travelers, Solo Travelers

Group Seating

Group Travelers, Families

Group Seating

Integrated power and room for three. The couch aims to serve families and indicates to passengers traveling alone that this space is for groups.

Individual Seating

Integrated power and a clear indication of whose space is whose.

Worksurface

Integrated power, task seating with room to spread out, integrated lighting.

Wobble Stool

It's ok to have fun! The wobble stool provides seating for both kids and adults looking to burn some energy.

Lockers

Lockers allow passengers to leave their bags and roam the terminal freely. The lockers are inside the TSA secured area and open with the scan of a boarding pass.

Accessories

Integrated lighting makes the system feel more residential and cosy in the airport. Privacy shields, endcap seating, and tables make smart use of space and attach using the rail system.

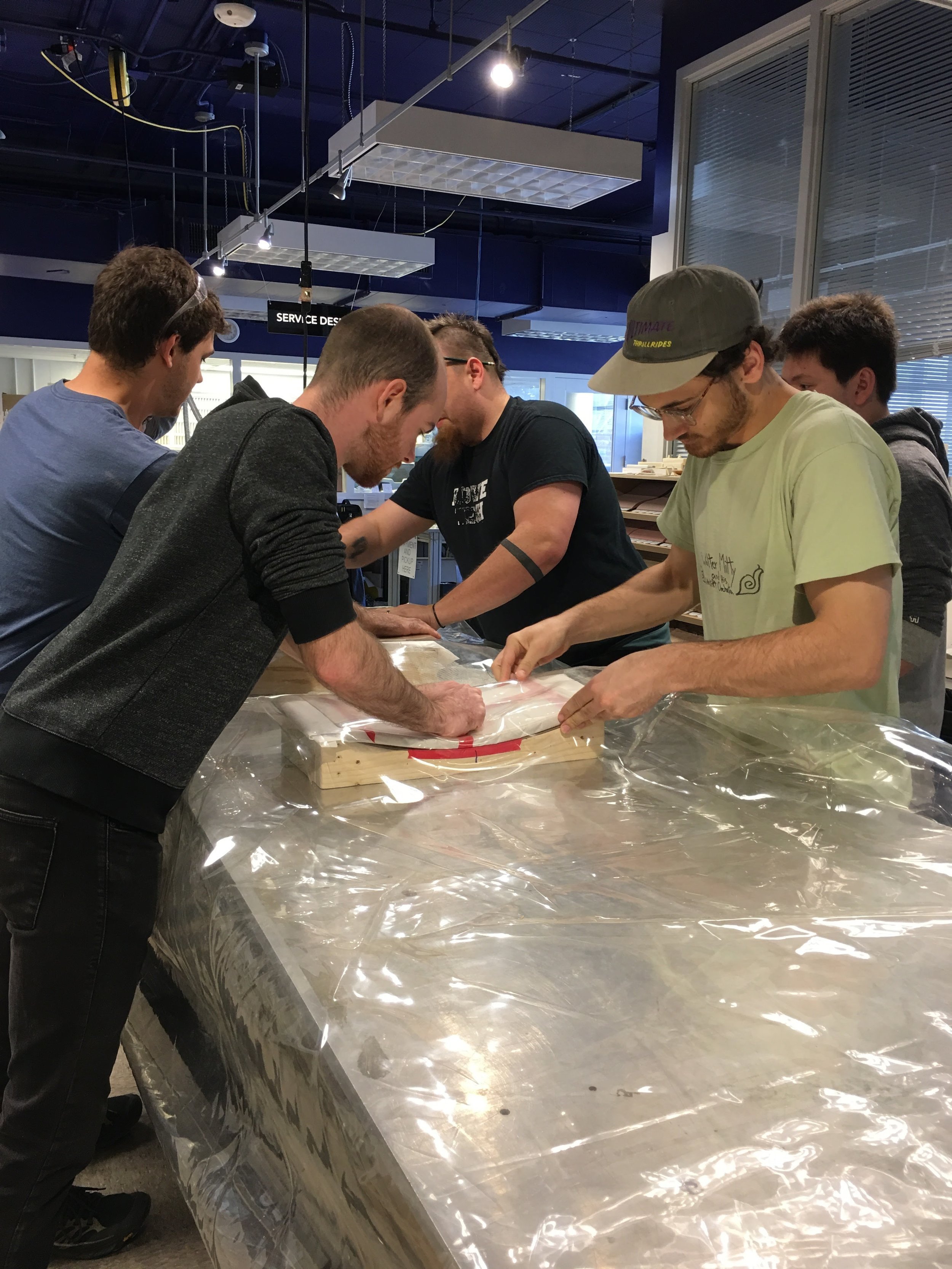

Full-scale Prototype

For DAAPworks 2017, I created a full scale, sit-able model of three of the modules – the worksurface, the single seat, and the couch. I bent plywood, created aluminum sand casting molds, had steel tube bent and powder coated, designed custom upholstery, and 3D printed master parts which were then cast in plastic.